Product Description:

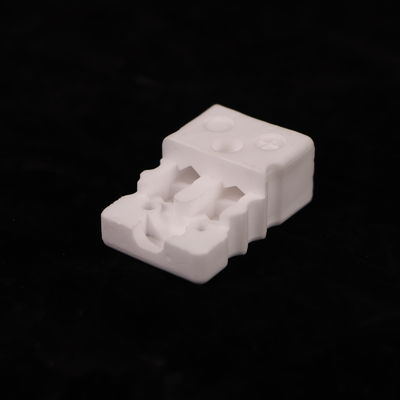

The Aluminum Oxide Ceramic product, commonly known as 95% Alumina ceramic plate, is a high-performance material widely used in various industrial applications due to its exceptional mechanical, thermal, and chemical properties. This alumina ceramic is renowned for its outstanding compressive strength, hardness, thermal stability, and durability, making it an ideal choice for components that require a combination of toughness and wear resistance.

One of the most significant attributes of this alumina ceramic substrate is its impressive compressive strength, which exceeds 3000 MPa. This high compressive strength ensures that the material can withstand substantial loads and mechanical stresses without deformation or failure, making it suitable for heavy-duty applications such as wear parts, cutting tools, and structural components in demanding environments.

The hardness of the 95% Alumina ceramic plate is rated at 9 on the Mohs scale, which places it among the hardest ceramic materials available. This exceptional hardness translates to superior wear resistance, allowing the alumina ceramic to maintain its surface integrity even under abrasive conditions. This property is particularly beneficial in industries requiring materials that resist scratching, erosion, and surface degradation, such as in the manufacturing of protective coatings, electrical insulators, and precision machining parts.

Thermal expansion is another critical property of this alumina ceramic substrate. With a thermal expansion coefficient of 8.9 x 10 -6 /K, the material exhibits excellent dimensional stability under varying temperature conditions. This low thermal expansion rate minimizes the risk of thermal shock and structural damage when exposed to rapid temperature changes, making it highly suitable for applications in electronics, aerospace, and automotive industries where thermal cycling is common.

The flexural strength of the Aluminum Oxide Ceramic product ranges between 200 to 400 MPa, indicating its ability to resist bending forces without breaking. This flexural strength ensures that the alumina ceramic substrate can endure mechanical stresses encountered during handling, assembly, and service life, providing reliability and longevity in structural and load-bearing applications.

Additionally, the density of the 95% Alumina ceramic plate typically falls between 3.75 and 3.9 g/cm 3 . This moderate density offers a balance between strength and weight, making it a practical material choice for components where both durability and manageable weight are essential. The relatively high density also contributes to the material’s excellent thermal conductivity and electrical insulation properties, which are critical for many technical applications.

Overall, the Aluminum Oxide Ceramic product is a versatile and robust material that combines high compressive strength, outstanding hardness, low thermal expansion, and significant flexural strength with a balanced density. These attributes make the 95% Alumina ceramic plate an indispensable material in industries such as electronics, automotive, aerospace, chemical processing, and manufacturing. Whether used as an alumina ceramic substrate in electronic devices or as wear-resistant components in mechanical systems, this material delivers exceptional performance and reliability.

In summary, the alumina ceramic’s superior mechanical properties, thermal stability, and chemical inertness position it as a leading choice for engineers and designers seeking to enhance the durability and efficiency of their products. The 95% Alumina ceramic plate represents a cutting-edge solution that meets the rigorous demands of modern industrial applications, ensuring long service life and excellent performance under challenging conditions.

Features:

- Product Name: Aluminum Oxide Ceramic

- Breakdown Voltage: >20 KV

- Hardness: 9 Mohs

- Dielectric Strength: 18-20 KV/mm

- Dielectric Constant: 9.6

- Poisson's Ratio: 0.25

- High temperature use alumina ceramic plate with excellent thermal stability

- Durable alumina ceramic suitable for high temperature applications

- Superior alumina ceramic offering high dielectric strength and breakdown voltage

Technical Parameters:

| Dielectric Constant |

9.6 |

| Young's Modulus |

200-400 GPa |

| Density |

3.75-3.9 g/cm³ |

| Poisson's Ratio |

0.25 |

| Tensile Strength |

200-400 MPa |

| Thermal Conductivity |

25-35 W/mK |

| Breakdown Voltage |

>20 KV |

| Thermal Expansion |

8.9 x 10 -6 /K |

| Flexural Strength |

200-400 MPa |

| Compressive Strength |

>3000 MPa |

Applications:

The KAMTAI Aluminum Oxide Ceramic product, model number KT-YHL, is a premium-quality 99% Alumina ceramic plate manufactured in China. With ISO 9001 certification, this product meets stringent international quality standards, ensuring reliability and consistency for various industrial applications. The aluminum oxide ceramic material used in this alumina ceramic plate offers exceptional mechanical and electrical properties, including a tensile strength ranging from 200 to 400 MPa and a Young's modulus between 200 and 400 GPa. These characteristics provide excellent durability and resistance to wear and deformation, making it ideal for high-performance environments.

This high temperature use alumina ceramic plate is specially designed to withstand extreme thermal conditions, thanks to its outstanding thermal stability and a dielectric constant of 9.6. It also boasts a breakdown voltage greater than 20 KV, ensuring superior electrical insulation performance. These features make the KT-YHL alumina ceramic plate suitable for applications requiring both high mechanical strength and excellent electrical insulation, such as in electronics, electrical engineering, and high-temperature industrial processes.

Common application occasions for the 99% Alumina ceramic plate include use in thermal insulation systems, electrical components, wear-resistant parts, and as substrates in semiconductor manufacturing. Its high temperature resistance and mechanical robustness make it perfect for furnace linings, heat exchangers, and other high-temperature environments where materials must maintain structural integrity under thermal stress.

The alumina ceramic plate is also widely employed in industries such as automotive, aerospace, electronics, and chemical processing. In automotive applications, it serves as a protective component for engines and exhaust systems exposed to high heat and corrosive environments. In the electronics sector, it is used for insulating substrates and components that require stable dielectric properties at elevated temperatures.

KAMTAI offers this alumina ceramic plate with a minimum order quantity of 300 pieces, packaged securely in wooden boxes to ensure safe delivery. The supply ability is strong, with a production capacity of 500,000 pieces per month. Customers can negotiate pricing based on order volume. Delivery time is typically 30 days after payment, with payment terms via TT, allowing for smooth and efficient transactions.

Overall, the KT-YHL aluminum oxide ceramic product is a versatile and high-performance solution for industries that demand durable, high temperature use alumina ceramic plates with excellent mechanical and electrical properties.

Customization:

KAMTAI offers high-quality Aluminum Oxide Ceramic products, specifically the KT-YHL model, proudly made in CHINA and certified with ISO 9001. Our alumina ceramic plate is designed for high temperature use, ensuring excellent performance and durability in demanding environments. With a minimum order quantity of 300PCS, we provide competitive pricing that is open for negotiation.

The 95% Alumina ceramic plate boasts superior mechanical properties, including a flexural strength of 200-400 MPa, tensile strength of 200-400 MPa, and a density ranging from 3.75 to 3.9g/cm3. It also features a dielectric strength of 18-20 KV/mm, making it an ideal choice for electrical insulation applications. The product comes in a pristine white color and is carefully packaged in a wooden box to ensure safe delivery.

We guarantee a supply ability of 500,000PCS per month, with a delivery time of 30 days after payment. Payment terms are via TT, providing a secure and efficient transaction process. Trust KAMTAI for your alumina ceramic plate needs, combining quality, reliability, and excellent customer service.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!